Radio shuttle is a racking system with high density storage including racking and electrically powered pallet runners which works with forklifts. The high efficient storage solution provides a new option to maximum use of warehouse volume.It makes a new concept for loading pallets and storage space, utilizes the warehouse space more adequately and flexibility comparing with other traditional

storage styles.

Product extension design

Combined shuttle racking: Combined shuttle racking system is a full automatic intensive storage system which consist of month-and-child shuttle, guide rail, racking, hoist, pallet conveyor, automatic control system, RWCS and WMS. Shuttle and Bridge stacking system: Intelligent shuttle collaborate with warehouse stacker in WCS planes. They will manage the whole position together, which will largely increase management range of stacker. Multi-level Shuttle warehouse system: Traditional multi-level warehouse system, is one single level add on another in case to make full use of space. Due to high loading requirement of building floors, it leads to high cost and waste of space in height.

The Shuttle Systems runs underneath the pallet loads on rails, delivering and extracting pallets within a deep lane rack system. Working in either FIFO or LIFO applications, the Shuttle Systems significantly improves throughput by indexing loads directly to the first pallet position at the aisle face. Using a RF controller, the operator can instruct the electro-mechanical platform to lift, lower, or shuttle pallets to the desired position; or program the system to run various predetermined functions.

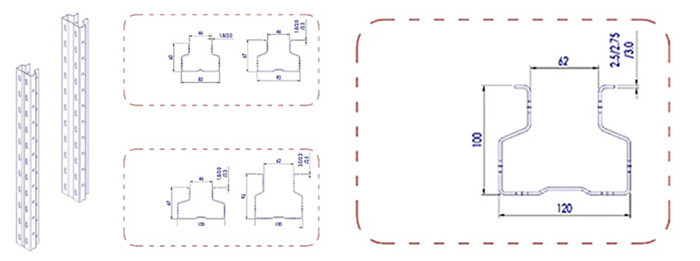

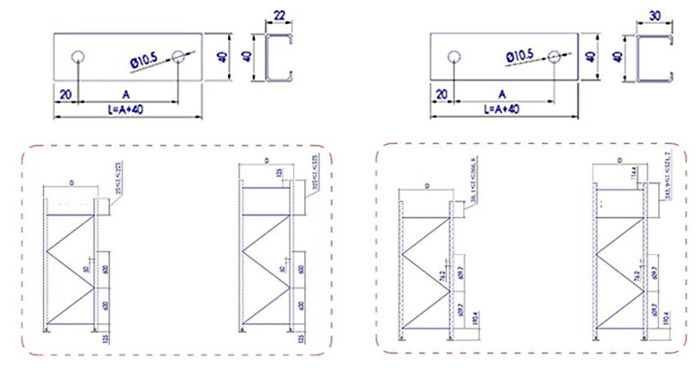

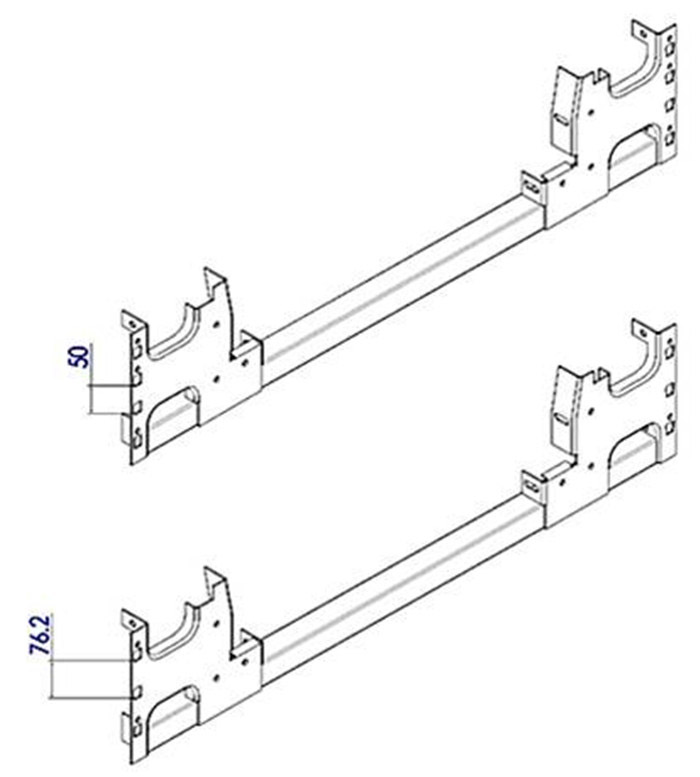

Radio Shuttle Racking CAD

Radio Shuttle Racking Upright: Material: Hot-rolled steel coil Feature : Molding In One; Multi- fold surface; large loading. Noted : 90 type and 100 type is normal post. Horizontal&diagonal bracing:

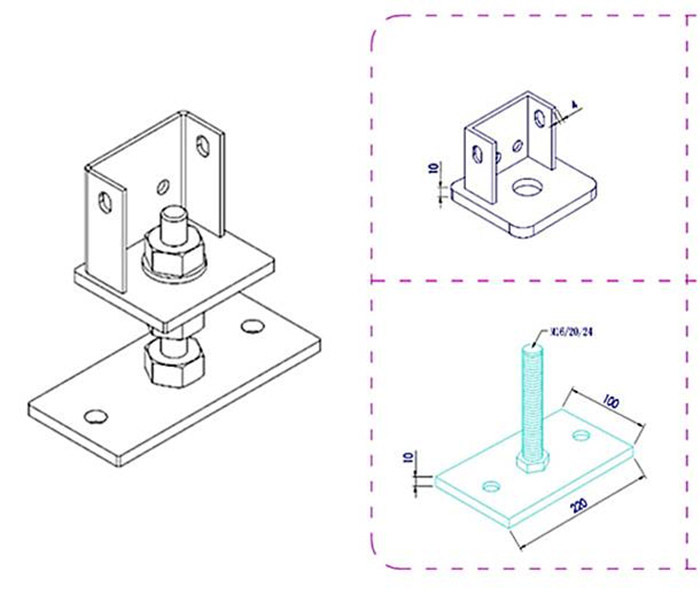

Horizontal&diagonal bracing: Radio Shuttle Adjustable basement: Adjustable basement-top: Specification: thick 10t/4t, dimension according to post, surface paint color is same as upright Appliance:80.90.100.120 type upright Adjustable basement-bottom: Specification: M16/20/24*180, Level 4.8, galvanization, Adjustable limits 0-60mm Loading:M16≤2.5tons/pcs;M20≤6tons/pcs;M24≤8 tons/pcs Appliance:M16 matches 80 post, M20/24 matches 90 and 100 post

Radio Shuttle Adjustable basement: Adjustable basement-top: Specification: thick 10t/4t, dimension according to post, surface paint color is same as upright Appliance:80.90.100.120 type upright Adjustable basement-bottom: Specification: M16/20/24*180, Level 4.8, galvanization, Adjustable limits 0-60mm Loading:M16≤2.5tons/pcs;M20≤6tons/pcs;M24≤8 tons/pcs Appliance:M16 matches 80 post, M20/24 matches 90 and 100 post

Radio Shuttle Support Beam: Specification: 50*50*1.5 square tube, 200KG≤each pallet capacity≤1500KG 50*30*1.5 rectangle tubes, each pallet capacity<500KG Material: Hot rolled welded pipe and hot rolled steel plate Function: connect connector, fix and support the cargos on the rail Feature: Molding In One, Multi- fold surface, high strength, large loading

Products scope :

- A large number of samples, such as food, beverages, chemicals, tobacco, etc.

- Cold storage function: Reduce cold working time, improve work efficiency and role safety!

- Term management: warehouses with stringent requirements for batches of items, warehouses that require first-in, first-out operations management

- Increased storage capacity: warehouses with limited storage space that require maximum use of space

Product pictures