Push back pallet racking systems provide users with the unique advantage of increasing the number of pallet and have minimal impact on accessing SKUs. Due to its easy to use and ability to increase the storage density of pallet, the popularity of push back pallet rack has soared in recent years.

In terms of initial costs, push back racks are often more expensive than selective racks or drive in pallet racks. However, the improvements in efficiency and storage density can produce long-term profits, which in turn can drive smart investment in many applications. Like many dynamic systems, push back racks are usually partially constructed from structural racks at least.

Features & Advantages:

- Better use of available pallet space than most storage systems

- Allow more SKUs to be stored

- Save labor and forklift drivers do not have to remove jammed pallets

- Enjoy more rack area with single-aisle design

- Load/unload pallet easily and quickly

- Each lane is FILO, but FIFOs can be easily implemented with proper design

- Low sealing bearing maintenance requirements

- Customizable pallet cart and it usually color coded to ensure safety and ease of use

- Small cart stack provides maximum storage height

- Forklifts never have to enter the rack to prevent damage to the rack

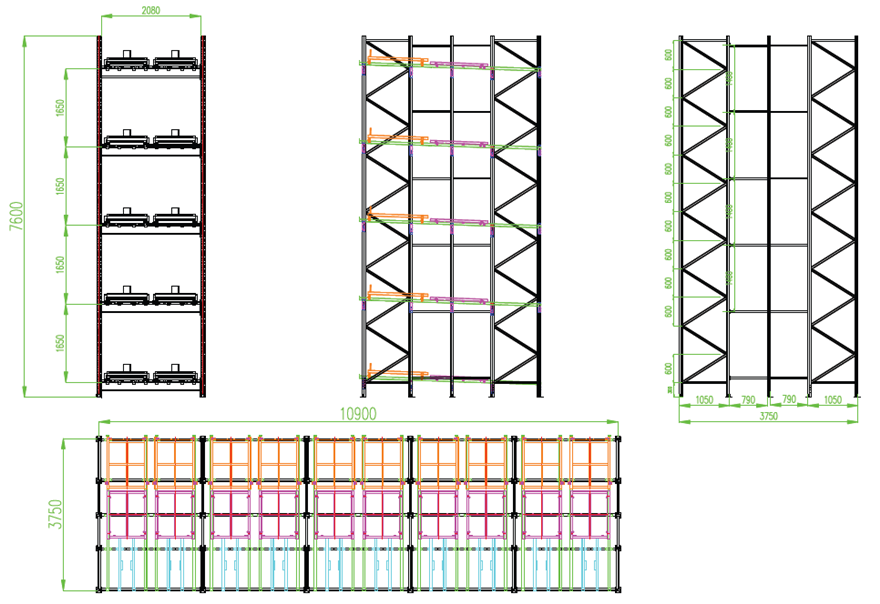

Product CAD layouts:

Packaging & Shipping:

Gulf Shelving pay great attention to export package ,which aims at protecting our goods from being damaged during transportation, loading or unloading.Our packs can use forklift to unload the container easily and such can be able to greatly save labour cost.