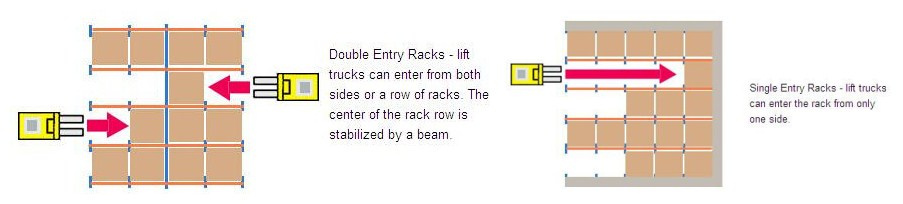

Drive in pallet rack and drive thru racking are terms that are often used interchangeably.It is difficult to differentiate between the two in some environments. Generally, drive-in racking requires operators to drive into the racking system from one side and remove pallets from the same entry point. Some drive-in rack systems have a wall or otherwise closed at the opposite end.

Drive-in & drive-through Racks offer the ability to store a large amount of similar product loads in a smaller area. Selectivity of product species is restricted, but storage density is outstanding. Drive in racking can store up to 75% pallets in the same space than selective racking which depends on your application. It requires fewer aisles and better cubic storage. A simple way to identify a drive-in rack systems is its LIFO inventory management. Product is rotated in a Last-In First-Out inventory manner because of the single entry/exit point.

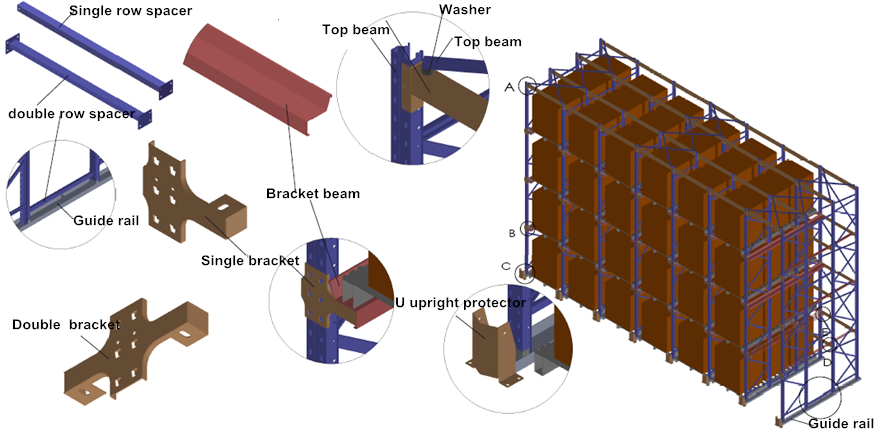

Drive in pallet rack layout:

| Product Name | Drive In Pallet Racks |

| Customized Specification | Drive-in Racking is available in a range of sizes and configurations. Please call or email us and we can work together to get the most cost-effective and practical solution. |

| Pallet Rail Levels | 2 levels, 3 levels, 4 levels, 5 levels |

| Load Capacity per Pallet | 500KG, 800KG, 1200KG, 1500KG, 2000KG |

| Raw Material | High quality cold rolling steel |

| Material Thickness | 1.5mm, 1.8mm, 2.0mm, 2.5mm |

| Surface Treatment | powder coated |

| Rack Colors | standard blue, orange and customized available |

Sample CAD layouts for your reference:

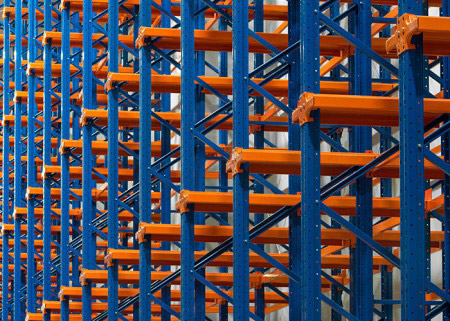

Product pictures